-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

Nissei ASB has developed many specialized techniques enabling enormous flexibility of production.

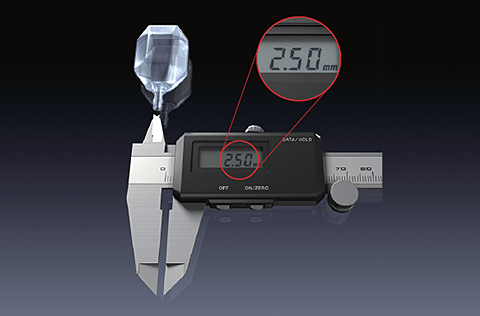

By utilizing a special preform molding technique combined with re-shaping of the preform at the conditioning station, our ASB Series models can mold containers with a neck bore diameter as low as 2.5mm suitable for very small containers.

ASB

Using special injection mold design that changes shape during injection molding, or by double-layer molding base thicknesses of 10mm or more can be achieved while maintaining perfect clarity. The finished visual impression is a PET container that is indistinguishable from glass. Combine this with a thick wall to produce the extreme high quality for premium cosmetic products.

Injected Shoulder

ASB

Where a specialized container shoulder is required having exceptional detail for market appeal or precise capping, the shoulder can be molded as a flange on the preform in the injection cavity.

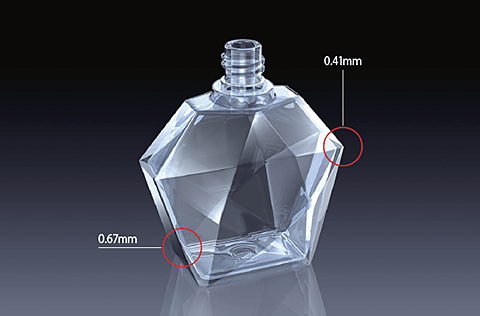

Sharp Corner Molding

ASB’s conventional 4-station molding Injection Stretch Blow Molding (ISBM) process utilizes the second station to control the preform precisely. With suitable molds, this is especially useful for molding small bottles in a variety of materials that feature extremely sharp corner radii of 0.24-0.97mm, even in PET.

Canted (Tilted) Neck

ASB

For a wide range of container designs including baby feeding, engine oil, shoe polish, etc., this specialized feature provides distinct advantages for feeding, pouring or application at difficult angles. It can also be used to simply provide eye-catching visual appeal to aid in product marketing in a variety of molding materials.

Stackable

ASB/PF/HSB

By blow molding with a deeply inset base, containers can be stacked directly on top of each other reducing volume for storage and transportation and reducing interlayer packaging materials.

※ Some models may require option parts.

Deep Pinch Grip

With ASB’s deep pinch grip technology, containers can be molded having handle grips much deeper than has ever been possible before. The result is the ability to mold large containers that can be comfortably held by everyone.

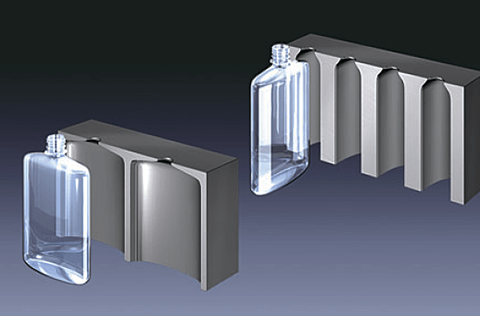

Front Parting Line

Thanks to our high quality mold manufacturing techniques, parting lines are virtually invisible. By designing oval containers with the parting line on the front / rear face, cavitation and productivity can be raised by up to 80%.

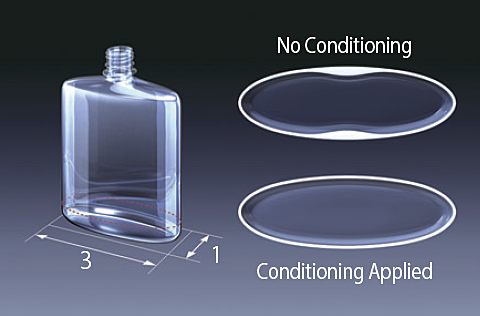

Extreme Oval

Preforms can be molded using ovalized injection cores or cavities. Preform temperature can be modified by use of ovalized conditioning station components (ASB), or Preferential Heating (PF). As a result, high ovality ratios are easily achieved while maintaining perfectly equal wall thickness.

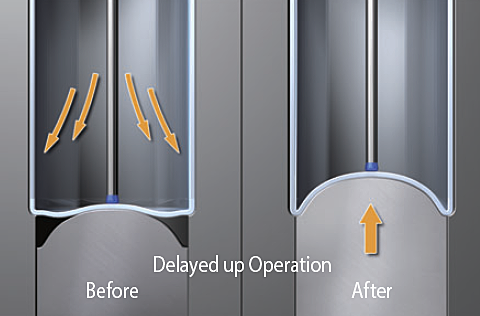

Champagne Base

ASB/PF/HSB

Deeply dished bases for pressurized containers can be easily molded using the built in “bottom mold delay” of the molding machine with an appropriate mold design.

※ Some models may require option parts.

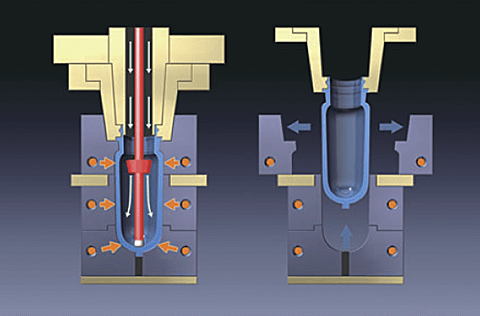

Split Type Conditioning Blow

An ASB Series machine can utilize split type conditioning blow in order to stretch blow mold polypropylene narrow necked containers with increased molding stability. The technique can also be used to more easily mold very thick walled PET containers.

Handle Molding

A variety of handled bottles can be molded including post-molding and in-mold types (ASB/PF) and integral (PF). By applying spot cooling in the conditioning station, the preform is stretch blown to the ideal condition for stable molding of handled containers.

PET Can

ASB

The ability to injection mold a very thin flange means the container can go through the standard aluminium can lid crimping process. A transparent container enhances the product appeal.

Off-Center Necks

Household trigger spray and similar containers are often designed with necks that are off-center. At ASB we have many experiences with this type of container design and can offer off-center ratios as high as 2:1 (standard) , 7:3 (specialized).

Fixed Neck Orientation

Since the neck of the container is held throughout the molding process (ASB), the neck will always be in the correct orientation. Users of PF Series machines can achieve the same result with the optional neck orientation system.

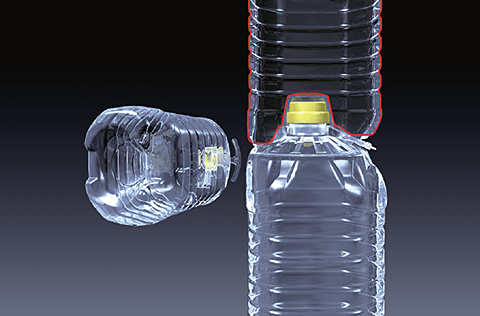

Super Light Weight/Collapsible

ASB/PF

Extreme light weight body allows the container to collapse. Applications include hygienic water server bottles to eliminate incoming airborne viruses, folded storage prior to filling, efficient compacting of recycled containers.

Asymmetric Parting Line

ASB/PF

ASB’s superb quality blow mold manufacturing allows complex container shapes with undercuts to be molded by designing the blow mold parting line off the normal axis.

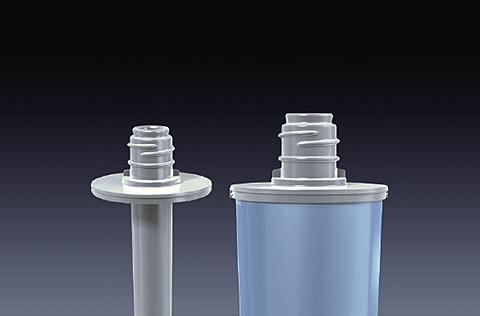

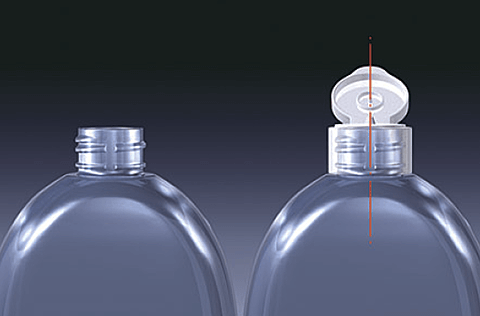

Complex Neck Design/Very Short Necks

Since the preform is custom designed for the container, the end user can specify virtually any neck that is moldable (ASB/PF). In ASB Series machines, the neck of the container can be as short as 3mm allowing greater flexibility on cap design and lighter weight.

Zero/Minimum Support Ring

Containers molded in ASB Series machines do not require any support ring as the neck is always firmly held by the molded threads. In PF Series machines, the support ring diameter can be as low as 2mm greater than the preform diameter. Weight can be saved and the appearance is enhanced.

Bottle-to-Bottle Recycling

With the simple addition of a specially designed PET resin dryer, ASB’s full range of machines can mold suitably re-processed post-consumer resin directly into many containers for a wide range of applications, contributing toward a cleaner environment and cost reductions in raw materials.