-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

Nissei ASB is able to offer an efficient and superior service by utilizing the international talents of our global design,

manufacturing and service personnel. In addition to our primary design facility in Japan where the focus is on group R&D and the design and assembly of custom built machinery,

our India factory takes prime responsibility for manufacturing. In particular,

our state-of-the-art mold manufacturing facility in our India factory allows us to offer faster delivery times for molds from design through manufacturing and final product testing.

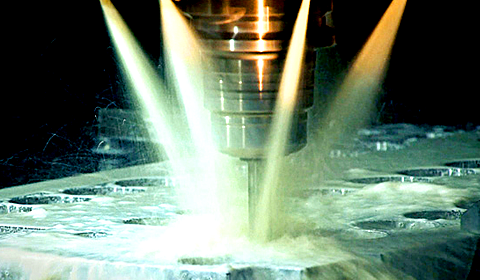

The recently expanded Mumbai factory currently employs more than 1,600 staff in 37,700m2 of total factory space that operates a 24 hour CNC machine tool unit providing the ASB group with the majority of its machining capability.

In addition, the factory manufactures and assembles many of our best-selling standard models of machines.

Back in the early days of injection stretch blow molding (ISBM), Nissei ASB was a pioneer in the field and PET was just becoming established as the material of choice for beverage and foodstuff containers.

Today, both Nissei ASB and PET remain firmly at the forefront of the injection stretch blow molding industry.

Our pioneering work was in the field of 1-step PET Injection Stretch Blow Molding Machines, the globally renowned “ASB Series” four-station machines are still in huge demand today for their proven stability and flexibility.

Combining the advantages of both the 1-step and 2-step production methods, in the mid-nineties, Nissei ASB developed the revolutionary 1.5-step “cool parison” method.

In 2004 we refined our highly successful 2-step reheat double blow system into the “HSB Series”,

dedicated to the production of high temperature hot-fillable heat resistant containers, and from 2010 we introduced specialized machines for production of hot fill jars,

opening up another chapter in the ongoing expansion of PET applications.

Nissei ASB is not only a maker of injection stretch blow molding machines - a major part of our business has always been the ability to offer full product design, mold manufacturing and product testing.

In fact, mold demand has been steadily increasing to the point where we now supply over 350* sets per month across our entire range of machines.

We know our molding machines better than anyone, it therefore makes sense that we know how to get the best performance from the mold.

Where necessary we may even customize the machine design or operation to enhance the efficiency for a specific project. *- Equivalent mold sets based on ASB-50MB

ASB's highly-experienced design department will advise you on optimizing product design. Our product designers can provide product design suggestions at the customer's request. Please contact us for details.

Our overseas production unit is state-of-the-art providing world class engineering. Using over 150 CNC machine tools, mold components are manufacturing to an exacting quality standard.

Full and vigorous component inspection means our customers can be confident they are getting the very best possible quality. An essential point when dealing with the increasing demands of the container molding industry.

In-house mold testing ensures that when the mold arrives in your factory, no further testing will be required. You can start producing containers and profits immediately.