-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

Applications

Heat-Set bottles and jars are commonly used for filling juices, teas, pickles,

sauces and other bacteria sensitive products under pasteurized conditions.

Typical filling and/or pasteurization temperatures will vary from 65 to 95°C* depending on the product to be filled.

Heat-Setting can also be applied to returnable/refillable containers that need to be rinsed at high temperatures.

This minimizes shrinkage and adds other advantages to the container such as improved stiffness and scratch resistance.

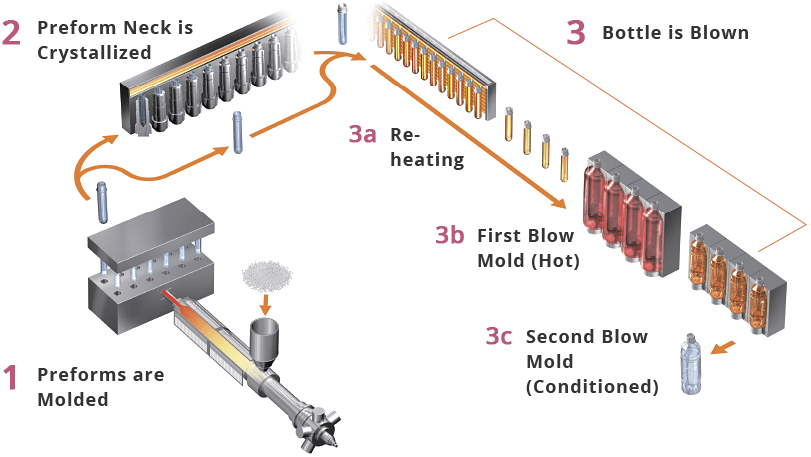

A PM Series preform molding machine may be used to injection mold the preform (as per normal 2-step molding). If neck crystallization is required, the molded neck diameter will typically be slightly larger than the target neck size.

A CM Series neck crystallizer is used. For bottles, crystallization is not always required;

the requirement depends on neck design,

filling procedure and what type of cap is to be used.

Using one of our HSB Series blow molding machines, the preform is re-heated and stretch blow molded. Refer to the following three steps for details of the HSB process.

The preform is re-heated to a temperature suitable for stretch blow molding. Up to this point, the molding process has been identical to conventional 2-step stretch blow molding but now it becomes different.

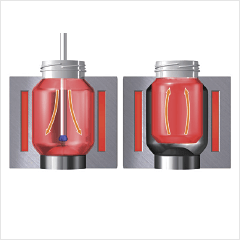

In an HSB Series machine, the primary blow mold is electrically heated in excess of 175°C, it is also larger than the target container size by around 20%. After blowing is completed, the pressurized air is exhausted from the container but the blow mold remains closed a little longer. The high temperature causes partial

crystallization of the molded container, additionally, the container shrinks which has the effect of removing stress from the PET polymer chains.

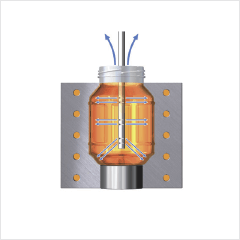

The shrunken and partially crystallized container is transferred into the secondary blow mold where it is blown to the final shape.

This mold is temperature conditioned to around 100°C. The final container leaves the mold with a high percentage of crystal growth and low stress. In the case of hot-filling, the container has the ability to be hot-filled at up to 95°C* or withstand pasteurization after filling.