-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

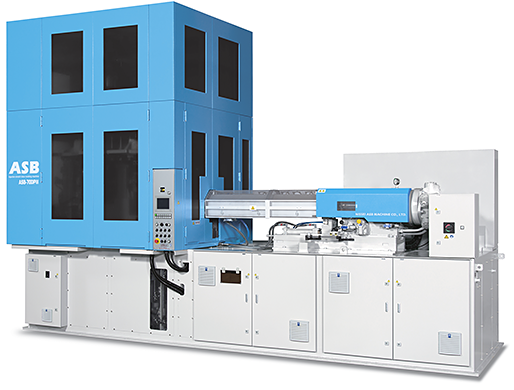

The ASB-70DP Series are mid-sized one-step injection stretch blow molding machines offering a perfect balance of productivity & flexibility that are available in two main variants, the “H” and the “W” model. Both models share a common overall size and structure, that contributes to simplified factory layout, faster operator training and reduced cost of maintenance. Whereas the “H” model provides extremely wide versatility for bottles and large mouth jars in up to 12 cavities, in the “W” variant the container molding portion - including the rotary table, stretch-blow unit and eject station - are re-engineered to enable double row molding of smaller containers with thread sizes up to 57mm diameter. This dramatically increases the potential productivity for bottles up to 1 liter capacity as available cavitation is doubled with up to 24 cavities being possible for containers up to 100ml capacity resulting in a machine that can produce up to 8,000bph* in an extremely compact floor area. * Subject to container specification

Cosmetics, pharmaceutical, liquor, general foods, medical, household, personal care, edible oil, mineral water, agrochemical, industrial, etc.

PET, RPET, PP, PEN, PLA, etc.

Plain round, non-round, oval, ultra-light, thick-wall etc.