-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

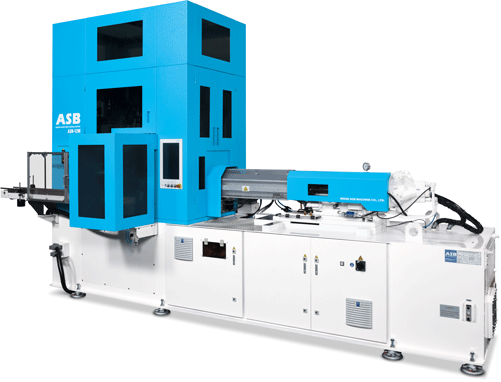

With a higher specification than the ASB-50MB, the ASB-12M is ideally suited to more demanding applications offering a wider range of molding options for pilot or full scale production. The machine has set new standards for higher cavitation with lower energy consumption through the use of servo driven hydraulic pumps. Molds from previous models can be fitted to this machine with simple modifications. With ASB’s Vision1 machine control system, the ASB-12M v2 makes a giant leap in terms of factory integration and ease of use.

Wide mouthed jars for a variety of food and non-food applications, Cosmetics (mascara, lotion, cream etc.), pharmaceuticals (eye drops, medicine, pills etc.), baby feeding bottles, spice, liquor, carbonated drink etc.

PET, PP, PC, PLA, PEN, PS, PES, PPSU, recycled PET etc.

Plain round, wide-mouth, oval, non-round, ultra-light etc.