-

- Search by Purpose

-

- Search by Series

-

- Catalog

- Ancillary Equipment

-

- To Investors

-

- IR Library

-

- Finance / Performance

-

- Share Information

No molding machine can operate without a range of ancillary equipment to provide pre-dried resin,air, water and other vital utilities. ASB can supply all your needs directly, or we can advise on correct specification and recommend supply from our range of preferred global partners.

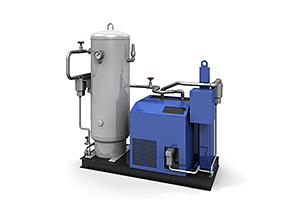

Without doubt, the most important piece of support equipment for the molding machine is a properly specified resin dryer. PET and many other moldable materials are hygroscopic and will suffer irreversible damage if molded without proper pre-drying. Machine efficiency and container quality would also be significantly reduced without a properly specified resin dryer.

In most parts of the world, ambient humidity will be high enough to cause condensation on chilled mold parts either on a seasonal basis or all year round. A mold dehumidifier is often essential, however factors such as altitude and location play a critical role in deciding if it is required.

An MTC is a highly useful device for conditioning various mold parts to specific temperatures for special processing such as heat setting, annealing and molding materials other than PET.

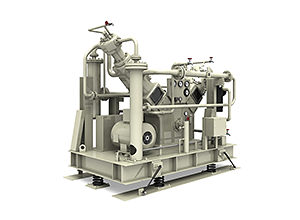

PET is a very stiff material so depending on the container design, up to 3.4MPa air pressure may be required to form the desired shape.

Many machine movements require compressed air at 0.7-1.0MPa for proper function. Not only our molding machine but downstream equipment such as packaging systems, leak tester etc. all require low pressure air.

Air Receivers must be appropriately sized to provide a stable reservoir of air pressure as process demand rises and falls. A stable air supply is essential in maintaining stable container quality. Compressed air contains moisture and airborne contamination that must be removed to prevent damage to the molding machine and other ancillary equipment. Often, these are integrated with the compressor system but may have to be specified separately.

The mold chiller's job is to take heat away from key areas of the molding process. Most significantly, the injected preforms need to have heat removed as fast as possible to offer best molding output and container quality.

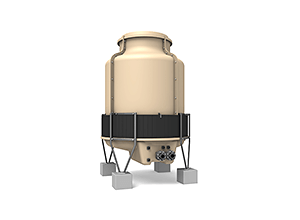

Evaporative cooling towers provide the most common method of eliminating waste heat from the entire molding process. Cooling tower water is used by almost every other piece of equipment including chillers, dryers, compressors and dehumidifiers.